Moisture in concrete is a fundamental factor in the flooring industry, but it need not be feared, just needs to be well understood and addressed with the system that works. S3 understands moisture and how it moves in concrete, which led us to creating a system level approach to addressing the many scenarios you will encounter in the field. S3 products are mix-and-match building blocks used to build solutions that meet your specific needs.

The set of solutions we can address with these products include but are not limited to:

- Concrete Curing & Waterproofing new slabs

- Mitigation of moisture vapor

- Ability to manage and isolate high RH and pH

- Solution for Sweating Slab Syndrome

- Isolation from chemicals used in asbestos adhesive remediation

- Fast track self-leveling & moisture remediation in single step application

MoistureShield™️ is a 3-in-1 solution for curing new slabs, and providing moisture vapor transmission protection and waterproofing the surface of both new and old concrete. It is a true total non-silicate based solution that eliminates the need for expensive and inconsistent concrete additives due to its patented technology.

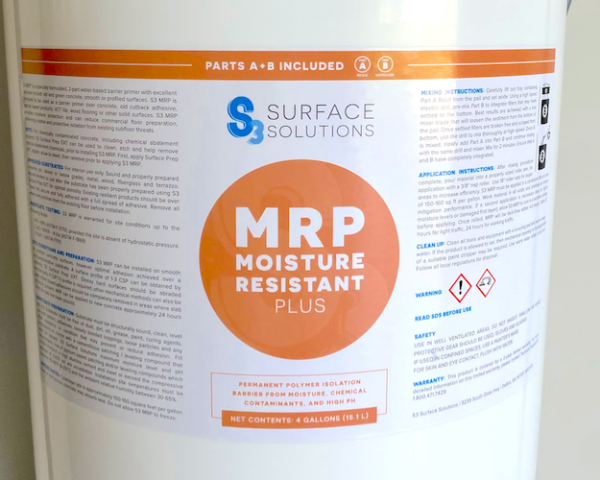

MRP Moisture Resistant Plus is a workhorse primer that can address a in a single coat a multitude of common floor prep issues including solutions for moisture vapor transmission(MVER), high RH & pH, asbestos remediation isolation, and general isolation over wood, metal, cutback adhesives, tiles, and other substrates.

125 MVP Primer is a 100% solids epoxy moisture remediation primer solution for green or old concrete, applied with roller over properly prepared and profiled concrete substrates.

Barrier SL is a true game changer. This non-portland based self-leveling mortar offers a built-in moisture vapor and waterproofing technology, saving you significant cost and shrinking the timeline on projects. The chemical bond to portland substrates in exceptional, it has fast return to service, and expedites the installation of finished flooring.