Situations

New concrete containing moderate moisture including hairline cracks. The competitor’s product was already on-site and early installs involved major labor efforts. Shot blasting was required and small areas had to be hand ground, which is very time-consuming. The competitor’s product outgassed and was difficult to skim coat and the installers had to walk around using a torch to remove out-gassing bubbles. As a result, the schedule fell behind.

Solution

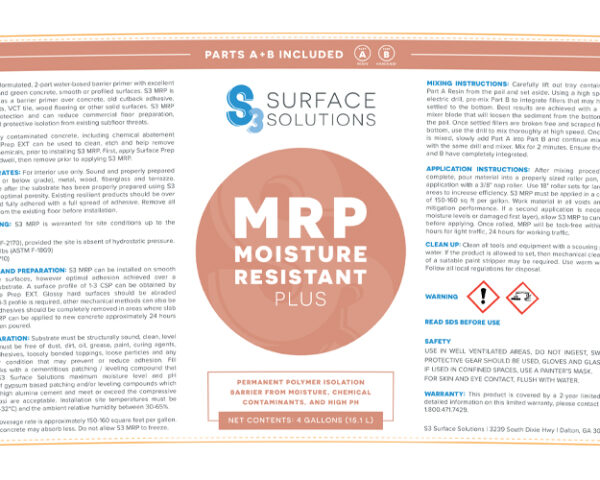

The flooring contractor chose to apply S3 MRP. First hairline cracks were primed with MRP then epoxy used to fill cracks adhered to MRP. Then MRP applied to the remainder of the concrete. Self-leveling installed as necessary to the MRP.

Result

Due to MRP, the job was completed ahead of schedule and under budget.

Unparalleled, Permanent Protection.

Our Low VOC, Resin-rich Proprietary Formula and Superior Cross-Linking Coatings & Sealants Reduce Total Cost of Ownership through: